MJC has provided superior HVAC coatings since 1989. Originating as a coating solutions provider, MJC offered coatings to HVAC systems before it was ever a factory option. MJC provides coating solutions that lead the market for anti-corrosion and anti-microbial protection.

MJC Applies three ranges of coatings for HVAC/R equipment:

1. Anti-Corrosive Coatings – protective coatings for harsh applications such as coastal, industrial and chemical applications.

2. Anti-Microbial Coatings – Protective coatings against bio growth on equipment surfaces.

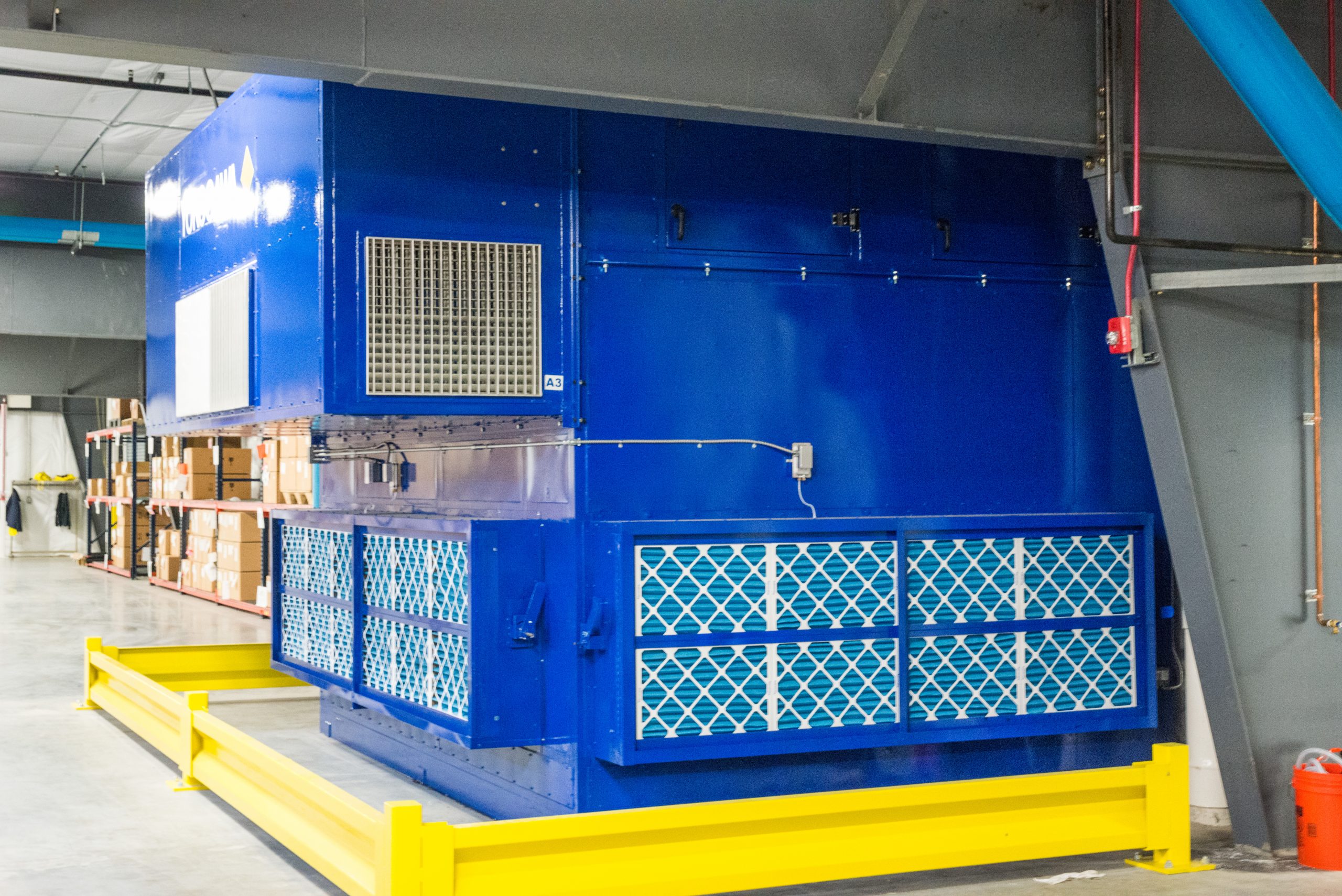

3. Architectural Coatings – Custom colors for HVAC equipment exterior casing.

Below are MJC’s coating applications and procedures:

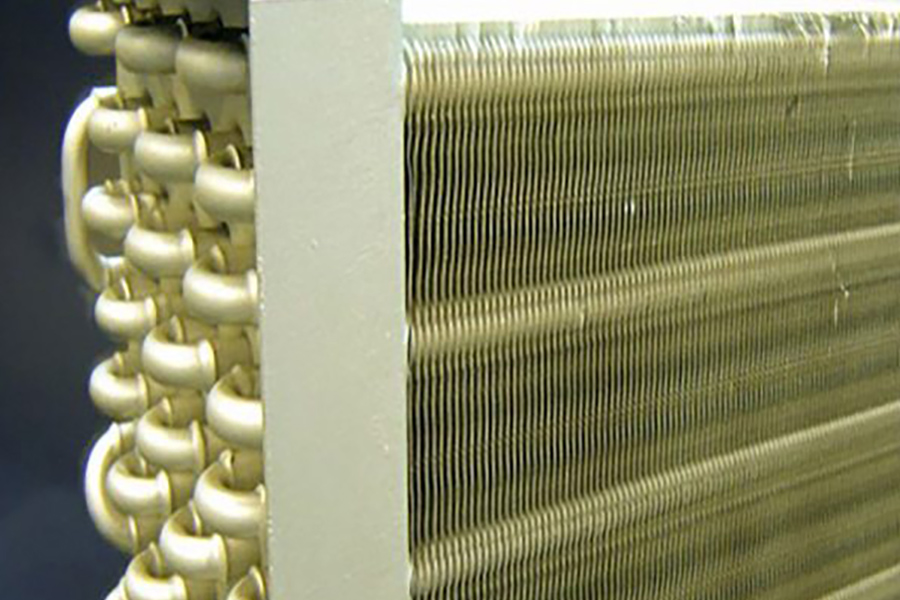

Loose Coil – loose coils coated with Blygold® PoluAl XT coil coatings. Headers and tubesheets coated with Sherwin Williams Acrolon™ Ultra acrylic polyurethane.

Coils-in-Units – coils in units are coated with Blygold® PoluAl XT coil coating. Headers and tubesheets coated with Sherwin Williams Acrolon™ Ultra acrylic polyurethane.

Coils + Refrigeration Circuit – coils in the unit are coated with Blygold® PoluAl XT coil coating. Headers and tubesheet and all exposed copper of the refrigerant circuit are coated with one layer each of Sherwin Williams Macropoxy® high-build polyamide epoxy and Acrolon™ Ultra acrylic polyurethane.

Casing/Cabinet Coatings – interior or exterior unit casing/cabinets are coated with Sherwin Williams Macropoxy® high-build polyamide epoxy and Acrolon™ Ultra acrylic polyurethane.

Casing/Cabinet Coat-All – entire unit interior/exterior casing/cabinet including piping, components, etc. are coated with Sherwin Williams Macropoxy® high-build polyamide epoxy and Acrolon™ Ultra acrylic polyurethane.

Interior Coat-Alls. – coils in the unit are coated with Blygold® PoluAl XT coil coating. The entire unit interior casing/cabinet including piping, components, etc. are coated with Sherwin Williams Macropoxy® high-build polyamide epoxy and Acrolon™ Ultra acrylic polyurethane.

Coat-Alls. – coils in the unit are coated with Blygold® PoluAl XT coil coating. The entire unit interior/exterior casing/cabinet including piping, components, etc. are coated with Sherwin Williams Macropoxy® high-build polyamide epoxy and Acrolon™ Ultra acrylic polyurethane.

Electronic Circuits & Components – provided as an add to any of the above listed services – all electronic circuits components are coated with Dolph’s Synthite AC-46 conformal polyurethane varnish.

Anti-Microbial Coatings – loose coils or coils-in-units coated with Blygold PoluAl XTMB anti-microbial coil coating

Architectural Coatings – unit exterior casing/cabinets are coated with Sherwin Williams Macropoxy® high-build polyamide epoxy and Acrolon™ Ultra acrylic polyurethane to custom match as customer’s desired color number.

For further information on MJC Coatings, please contact sales@mjcinc.com or fill out the information on the “Get a quote” tab on our website.